Line Stops

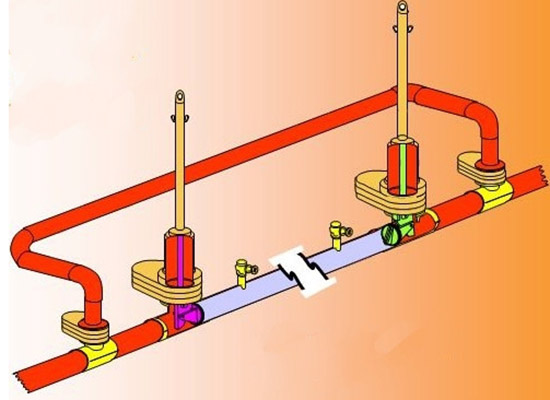

Line stops service is used to isolate piping systems that are in need of emergency repairs, alterations, or relocations. No matter what the need is, performing a line stop allows plant operator to successfully do so without shutdown the plant. Line stops can be used in conjunction with bypass lines in order to allow for a continual flow of product around the isolated section of piping.

Line stops service is performed after a hot tap has been completed and it is intended for isolating sections of the pipe temporarily. Therefore, line stops service allows plant operator for doing repair, maintenance, reconfiguration or valve insertion in online condition. Our line stops service can perform for low, medium and high pressure piping system as well as for vacuum piping system.

Inflatable line stops (bag stops) are an economical alternative to line stops when having issues of piping that are out of round or when inside surface conditions of the pipe prevent a standard line stops service. Bag stops are inserted into the pipe by using traditional hot tap technique and a bag stop insertion tool. Once inserted, the bag is inflated and the line content flow is stopped.